Pressurized Pipe Coating

NuLine™

Aquam’s NuLine™ pressurized pipe rehabilitation solution is used to rehabilitate pressurized pipe infrastructures including potable water, natural gas delivery, HVAC, and fire suppression.

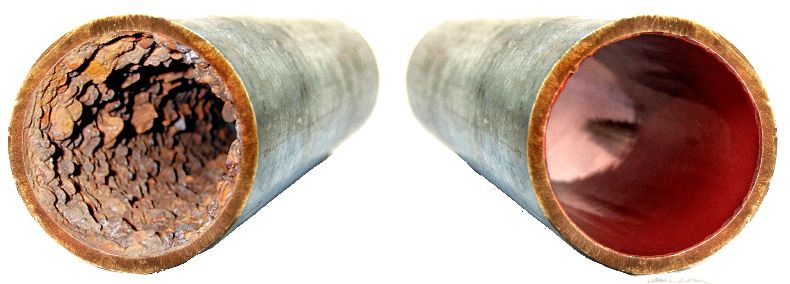

The NuLine epoxy barrier coating is a unique process derived from the result of over 7000 research hours dedicated to finding the perfect viscosity, air temperature, cure time and equipment needed to achieve optimal pipe adherence to provide a longer-lasting piping solution. Once the epoxy coating is applied to the interior of the pipe, it will seal and protect the system from further deterioration, dramatically extending the system’s life. The process can be used on a variety of pipe materials including galvanized steel, cast/black iron, and copper.

The process begins by draining the water out of the piping system and then running dry, heated air through the pipes to ensure the removal of any residual moisture. Next, the pipes are sandblasted clean, removing built-up corrosion in order to create an anchor tooth for the epoxy to adhere. Once the pipe is fully cleaned, the epoxy is blown into the piping system with filter instrument quality air. The pipe is fully coated which creates a barrier between the water and the pipe, helping prevent future corrosion and extending the life of the pipes.

Serline™

Aquam’s Serline™ pressurized pipe rehabilitation solution is used to rehabilitate lead service line pipes that deliver drinking water into residential and commercial properties. In the application process, a controlled air flow is used to evenly distribute Serline 266L, an environmentally safe and regulatory approved polyurethane/polyurea hybrid throughout the length of the pipe. The coating is smooth and durable, having a finish that is designed to be resistant to corrosion, mineral deposits, acids, petroleum products and alkalis. Serline 266L has been certified as meeting the rigorous requirements for compliance with NSF 61, Drinking Water System Components - Health Effects. NSF 61 applies to products that create barriers to isolate drinking water or prevent its contact with other surfaces, and was developed to assess the potential migration of contaminants from materials or products into drinking water.